USA

PRODE

Heavy Racking Systems

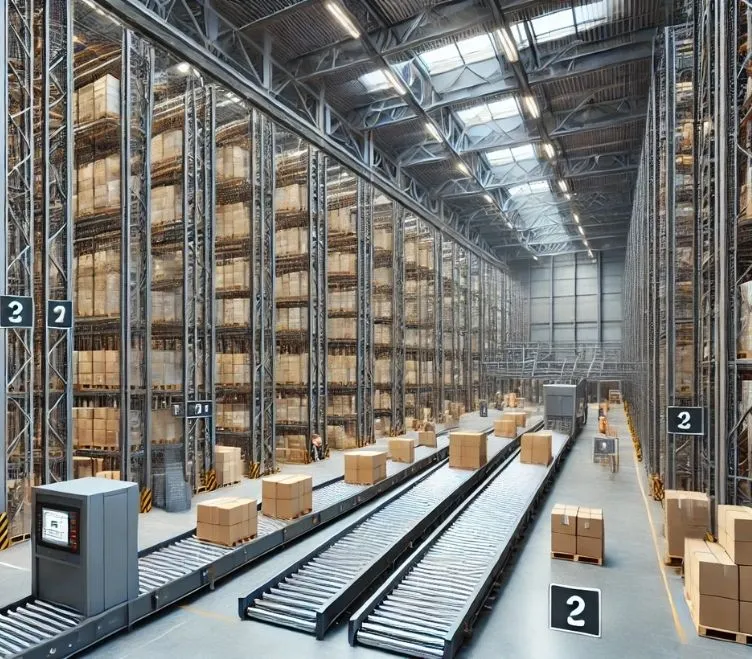

In industrial storage environments, efficiency and safety are critical components of success. Heavy racking systems, which can be integrated with conveyor systems and automation solutions, enable the safe transportation and storage of large loads. Especially in sectors requiring logistics, manufacturing, and high-volume storage, these racking systems are the key to optimizing business processes. In this article, we will explore the benefits of heavy racking systems, their applications, growth potential, and the value they bring to business processes.

Table of Contents

ToggleWhat Are Heavy Racking Systems?

Heavy racking systems are durable storage solutions designed to handle large and heavy loads. Made from robust materials like steel, these racks are ideal for storing wide and bulky products used in conjunction with pallets. They are commonly utilized in factories, large warehouses, and logistics centers. Their high capacities make them indispensable for businesses that must manage heavy workloads.

Benefits of Heavy Racking Systems

High Load Capacity

One of the primary advantages of heavy racking systems is their ability to safely carry very large and heavy loads. This makes them essential for industries such as automotive, construction materials, and metal manufacturing, where large and heavy products are prevalent. They can easily accommodate palletized loads and handle hundreds of kilograms, even tons of weight.

Durability and Longevity

In industrial settings, heavy loads must constantly be moved and stored. Heavy racking systems are built to last for many years in these environments. Thanks to their quality materials, these racks are resistant to impact and wear. While the initial investment cost may seem high, the long-term benefits, such as low maintenance requirements and durability, provide businesses with significant cost advantages.

Maximum Space Utilization

Heavy racking systems increase vertical storage capacity, allowing for the most efficient use of warehouse space. Especially in large warehouses, using racks that extend from the floor to the ceiling enables more materials to be stored. This helps businesses save on operational costs by allowing them to store more products in the same area.

Flexibility and Modular Design

Heavy racking systems have a modular structure, making them customizable according to storage needs. Businesses can expand or rearrange their racking systems based on the type and size of the loads. This provides a flexible storage solution that can adapt to varying business volumes and changing demands.

Workplace Safety

Storage solutions are critical not only for efficiency but also for workplace safety. Heavy racking systems are equipped with safety mechanisms that prevent overloading. Racks can be securely installed with stabilization systems that enhance stability, helping to minimize workplace accidents. This is especially crucial in high-rise storage environments, where risks of tipping or collapse are present.

Applications of Heavy Racking Systems

Heavy racking systems are used in a wide variety of industries:

- Logistics and Warehousing: In warehouses where large volumes of inventory must be stored, heavy racking systems ensure that heavy products are stored safely.

- Manufacturing Facilities: Ideal for the storage of raw materials, semi-finished goods, and finished products.

- Automotive Industry: Frequently used for storing vehicle parts, engines, and large metal products.

- Construction Sector: Facilitates the secure storage of heavy materials like construction supplies, steel beams, and pipes.

Integration of Heavy Racking Systems with Automation

Modern storage processes must be more efficient and faster than ever. Heavy racking systems work in perfect harmony with conveyor systems and automatic transport solutions. Integrating heavy racking systems with automation accelerates storage and logistics processes and minimizes human errors.

- Efficient Material Flow: When integrated with automatic conveyor systems, heavy racks enable fast and seamless movement of materials. This saves time and streamlines business processes.

- Automatic Picking Systems: Heavy racks, particularly when used with automatic picking systems, allow for faster and more efficient material management. These systems ensure accurate product picking and processing.

- Digital Inventory Management: Heavy racking systems can be integrated with digital warehouse management systems, making it easier to monitor stock levels and enabling error-free inventory management.

Growth Potential

Heavy racking systems have significant growth potential across various sectors due to increasing demand. With the rapid rise of digitalization and e-commerce, the need for logistics and storage solutions is also increasing. Businesses that handle large inventories can store more products using heavy racking systems, reduce operational costs, and optimize their business processes.

- Logistics and E-commerce: In the rapidly growing e-commerce sector, the usage of heavy racking systems will increase as businesses need to store a wide range of products.

- Construction and Manufacturing: Heavy racking systems are indispensable in sectors that require the storage of large and heavy materials.

Heavy racking systems provide robust, durable, and flexible solutions for storing large and heavy products, optimizing business processes. They enable businesses to increase efficiency and achieve cost advantages in the long term. These racking systems, which can be seamlessly integrated with automation solutions, are designed to meet modern storage needs. As a company specializing in conveyor systems and automation, we understand the contributions of heavy racking systems to business processes and how they can optimize storage operations.

For any business seeking reliable and flexible storage solutions, heavy racking systems are the key to unlocking growth and efficiency.

What are the safety standards for heavy shelving systems?

How can heavy shelving systems be integrated with automation?

What factors affect the efficiency of heavy shelving systems?

How does advancing technology influence the design and functionality of heavy shelving systems?

What sizes of products are suitable for storage in heavy shelving systems?

What are heavy shelving systems and how do they work?

Which industries utilize heavy shelving systems?

What is the installation process and requirements for these systems?

What is the maintenance and repair needs of heavy shelving systems?

What are the advantages of heavy shelving systems?