USA

PRODE

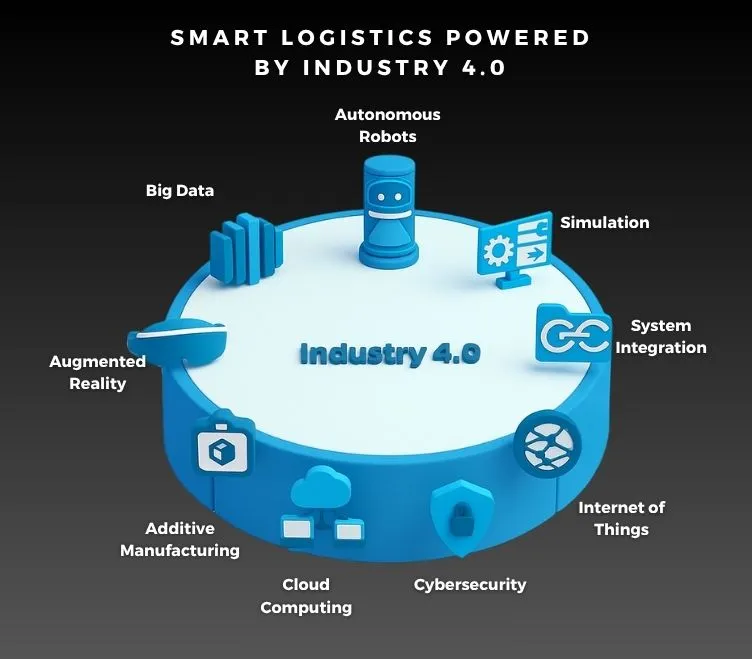

Smart Logistics Powered by Industry 4.0

Industry 4.0 has triggered a profound transformation in the worlds of manufacturing and logistics. With the integration of smart systems, efficiency increases while human error decreases. Especially in the field of smart logistics, recent developments are helping businesses gain a competitive edge. So, which technologies are shaping this transformation? Let’s explore how the Industry 4.0 cycle impacts smart logistics:

Table of Contents

Toggle1. Autonomous Robots

Manual labor is becoming less essential in logistics warehouses. Autonomous robots handle loading, unloading, and order picking with speed and precision.

2. Simulation

With large-scale data analysis, companies can simulate delivery routes, inventory planning, and potential delays. This speeds up and strengthens decision-making.

3. System Integration

All parts of the supply chain are now interconnected. Different software systems communicate seamlessly, allowing for real-time product tracking and smooth operations.

4. Internet of Things (IoT)

Thanks to sensors, vehicles, warehouses, and products stay connected. Real-time data such as temperature, humidity, and location are continuously monitored—especially vital for food and pharmaceutical logistics.

5. Cybersecurity

With data volume on the rise, cybersecurity measures are critical. Logistics systems are fortified with security layers to protect against cyberattacks.

6. Cloud Computing

Cloud systems offer cost-effective storage and flexible access to data from anywhere, enabling smarter operations and collaboration.

7. Additive Manufacturing (3D Printing)

From spare parts to packaging, 3D printing offers fast solutions, saving valuable time—especially in urgent logistics operations.

8. Augmented Reality (AR)

Warehouse workers can receive real-time guidance via smart glasses, increasing both safety and processing speed.

9. Big Data

Collected logistics data is analyzed to optimize customer behavior insights, stock needs, and shipping routes.

How does Industry 4.0 improve efficiency in logistics operations?

https://usaprode.com/smart-logistics-powered-by-industry-4-0/

What are the key benefits of smart logistics systems?

In what ways does big data enhance logistics performance?

How do autonomous robots transform warehouse management?

What are the advantages of real-time inventory tracking in Industry 4.0?

How is IoT technology used in modern supply chains?

How is simulation technology used in logistics planning?

What role does system integration play in Industry 4.0 logistics?

How can companies gain a competitive edge with Industry 4.0 logistics solutions?

What smart logistics solutions are offered on usaprode.com?

What’s the difference between traditional warehouses and smart warehouse systems?

Which logistics software solutions are compatible with Industry 4.0?

What are the core components of an Industry 4.0 automation system?

How does augmented reality increase warehouse efficiency and safety?

https://usaprode.com/smart-logistics-powered-by-industry-4-0/

Does Prode provide technical consultancy for Industry 4.0 projects?